What Does Motorcycle Parts New Zealand Specialists Mean?

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Table of ContentsMotorcycle Parts New Zealand Specialists - QuestionsThe Motorcycle Parts New Zealand Specialists IdeasHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Motorcycle Parts New Zealand Specialists Can Be Fun For AnyoneThe Of Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Mean?The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Get to out to one of our specialists today.CNC machining innovation is quickly becoming the focal factor of several manufacturing processes around the world as a straight result of its several advantages over other approaches. Additionally, the sectors that produce bikes have actually gotten on board with this pattern. The most ingenious firms are now creating their engine elements and wheels making use of machining techniques initially developed for motorcycle parts.

You might be wondering why we utilize. Currently that we have your focus allow us explain the reasoning behind this modern-day growth in the bike manufacturing market.

The 20-Second Trick For Motorcycle Parts New Zealand Specialists

In enhancement, you have complete control over the appearance of the components, also down to the minute information. Sometimes, motorcyclists might make a decision to spruce up their experience by installing aftermarket parts or customizing the bike's remodeling.

Getting My Motorcycle Parts New Zealand Specialists To Work

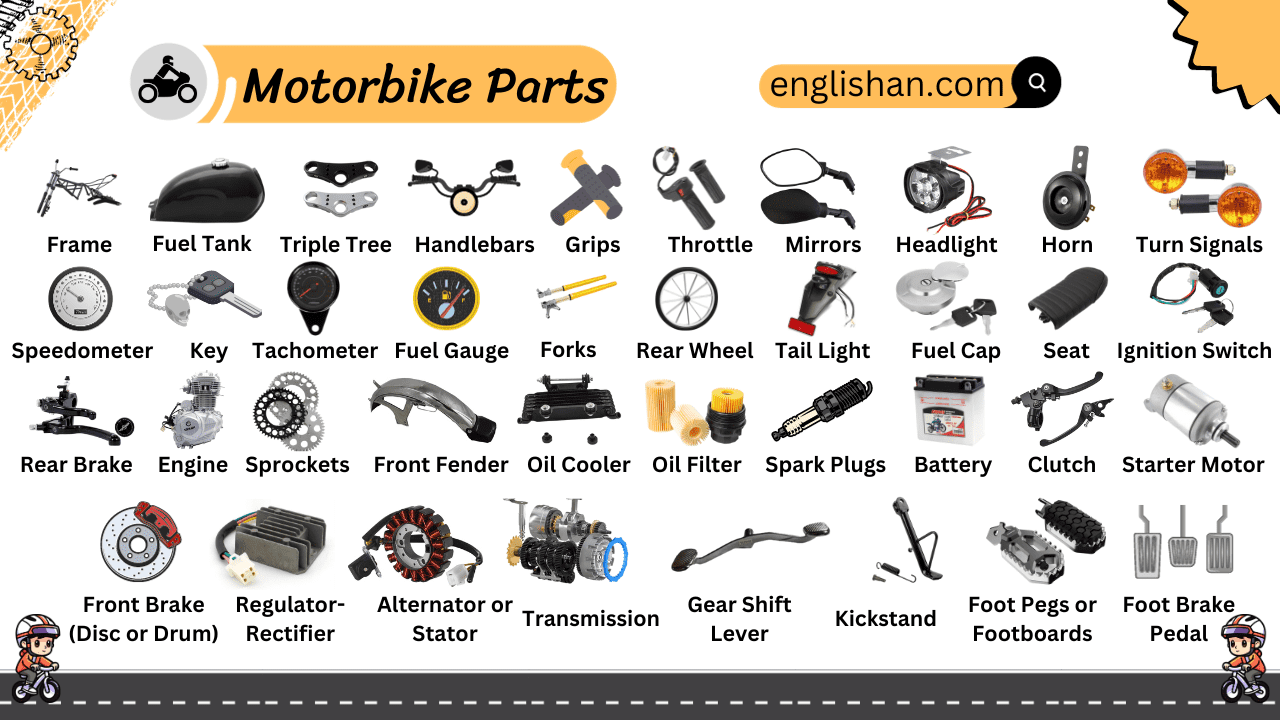

CNC machining might be used to make almost all of a motorcycle's metal and plastic elements. To continue, we'll talk about numerous machined parts for motorcycles.

Milling treatments are made use of to acquire the preferred level of wheel personalization. Another facet of the bike that might be personalized is the tires.

Not known Incorrect Statements About Motorcycle Parts New Zealand Specialists

When it comes to a car (or a motorbike), one of the most crucial component is the engine. A number of people suggest to it as the "heart" of the car. On the other hand, the camshaft, the cylinder head, and the pistons often tend to be elaborate and require styles with a high degree of accuracy.

Usage only top quality items, nonetheless, because these lights are critical for the safety of motorcyclists and other drivers or people on the road, specifically at evening. Motorbike fronts lights have three primary parts: the light bulb, or light source, the lens, and the real estate.

Milling procedures with a remarkable surface would cause the lenses having a reflective top quality that resembles that of a mirror. The cover, on the other hand, is not composed of breakable materials; instead, it is constructed out of hard polymers that can be machined right into more detailed patterns.

5 Easy Facts About Motorcycle Parts New Zealand Specialists Described

They commonly have fancy geometries with a wide range of min information. Motorbike makers commonly cast these parts, yet only for the manufacturing of bespoke components. Nevertheless, CNC machining is the method of choice when creating one-of-a-kind pieces. Machining on five axes in today's globe is the ways by which any design form may be understood.

The success of the procedure is contingent on the mill cutters' capability to compute subtle and difficult angles accurately. Pick Runsom for your customized bike parts! We have the capacity to make complex and fashionable elements making your bike incomparable. Most are crafted from light weight aluminum or steel alloys, each of which has its uses and advantages.

Below are a couple of examples of metals typically utilized in motorcycle part machining. Light weight aluminum is the key product utilized by companies focusing on generating customized motorcycle parts to develop most of these parts. Continue In the past, we would build our engines out of cast iron. On the other hand, aluminum is promptly becoming the material of selection, partially as a result of the truth that it is extra lightweight.

Zinc describes one more steel that is very light in weight and has great machining qualities due to its high mechanical toughness. This material may be developed right into almost any type of shape and keeps its measurements well. Also mission-critical components that need a high level of precision may take advantage of their usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

Another metal that sees hefty use in the production of CNC-customized components is magnesium. It is among the lightest metals that are currently available and has exceptional machinability attributes and toughness commensurate with its reduced find out weight. Among the downsides of magnesium is that its dust might easily catch fire.

Their most usual use in producing different motorbike components is fasteners, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them perfect for this usage.

The Only Guide for Motorcycle Parts New Zealand Specialists

It seems that CNC transforming and grating are the fundamental procedures. Nevertheless, different techniques exist, such as drilling. Let's examine a number of these machining techniques extensive. The CNC turning method is taken into consideration a subtractive production technique. Furthermore, it requires keeping bars of product, most typically plastic or steel, ready and then twisting a cutting device to eliminate areas of the material as the material is turned.

These approaches are just as important and create components with high accuracy and consistent quality. The procedures assist improve the overall high quality of the machined bike parts.

Motorcycle Parts New Zealand Specialists - Questions